Wired Interview Vice Interview Instructables Github

RELATED:

3D PRINTED RECORD

3D PRINTED RECORD

ARDUINODSP

ARDUINODSP

SUGARCUBE

SUGARCUBE

As a follow up to 3D printed records, I developed a more accessible way of fabricating records with a laser cutter. I wanted to try to extend the idea of digitally fabricating records to use relatively common and affordable machines and materials so that more people could participate and experiment with the process. So far I've successfully cut records from wood, acrylic, and paper, and I'm sure there are many more materials that would work. I wrote a Processing program to generate the record cutting paths from digital audio recordings so that it can be modified for any song, material, cutting machine, record size, and turntable speed; the files produced by this script can even be adapted to other CNC processes such as milling. Find the code and more detailed info about the project on Github and Instructables.

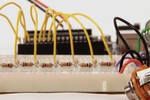

The main idea behind my code is to take an audio waveform and map it to a spiral on the record’s surface. If you look carefully at the closeup images of the record grooves, you can see a waveform embedded within them. These waves are cut laterally into the surface of the record and cause the needle to vibrate back and forth as it moves across the groove. The vibration of the needle is translated back into an electronic audio signal via a sensitive transducer.

All photos by Audrey Love.

These records were cut on an Epilog 120 Watt Legend EXT to a theoretical precision of 1200dpi (though the kerf of the cut and some tricks I used to avoid crashing the laser cutter dropped the actual precision down by ~1/6). The audio on the records has a bit depth between 4-5 bit and a sampling rate up to about 4.5kHz.

Bit depth is the per-sample resolution of the audio data. Most music is released at 16 bit, meaning each sample in the audio waveform can have one of 65536 (2^16) possible values. 8 bit audio has only 256 (2^8) steps of resolution and still sounds pretty close to the original. Music that is commonly referred to as "8-bit" like the music in early Nintendo games is actually 1 bit of resolution per sample; this low resolution is what gives it its unique and instantly recognizable sound, but with this project, I was aiming for something that sounds a little more organic.

Sampling rate is the amount of samples per second in a song. Typically, the sampling rate of a digital audio recording is 44.1kHz. When the sampling rate drops below about 40 kHz the higher frequencies of a song start losing their detail, but depending on the song you can go down to 20 or even 10 kHz sampling rate without losing any major details in the recording.

The Velvet Underground and Nico - Femme Fatale on plywood.

Radiohead - Idioteque on plywood. This song was ideal for the laser cutting process because of it's full mid tones and simple, synthetic drums. Live drums tend to contain a lot of high frequencies and noise, which does not translate well through this process. Laser cut records can't reproduce high frequencies because the kerf of the cut and the resolution of the machine do not allow for high enough detail to capture them; in a preprocessing step, all high frequencies are filtered out of the recording so that they don't produce extra noise on the track.

Velvet Underground - Sunday Morning on prefinished, curly maple.

Clear acrylic.

Curly maple closeup.

The main difference between these laser cut records and my 3D printed records is the orientation of the grooves. Since I couldn't reliably control the power of the laser while it's cutting a vector path, the grooves are cut laterally on the surface of the material. This means that the needle vibrates in the plane parallel to platter of the turntable. The 3D printed records are "cut" vertically; the needle vibrates perpendicular to the platter. I chose to modulate the grooves vertically for the 3D printed records because the vertical axis is the most precise axis on the machine. Stereo (2 channel) vinyl records are cut both vertically and laterally so that two isolated channels of audio fit into a single groove. Mono vinyl is typically cut laterally for better quality and higher dynamic range.

Clear acrylic.

Joy Division - Love Will Tear Us Apart on clear acrylic.

Paper record test. I had some trouble keeping the needle in the groove in my tests on paper. I found that defocusing the beam of the laser slightly so that it cut with a wider kerf and using a thick cardstock helped.